Drive Pulleys Tailored to Your Needs

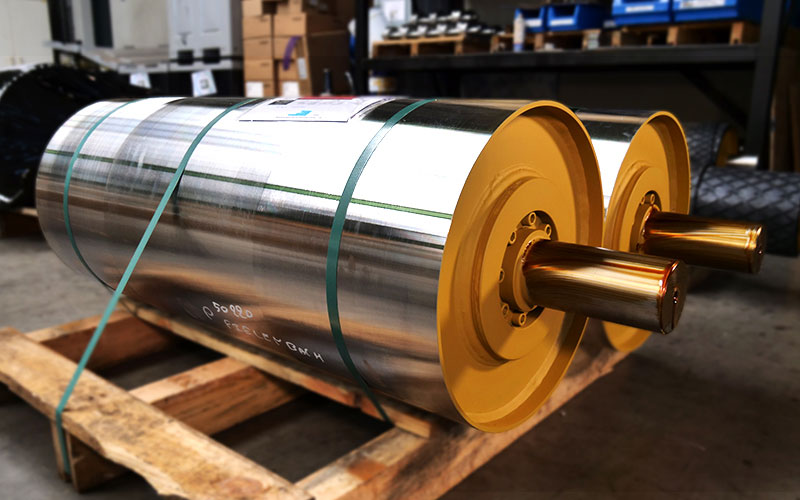

In every conveyor belt system lies the drive pulley, an essential component that ensures the system’s proper operation and the smooth movement of the belt. At ALTEMA, we understand the importance of reliable equipment in guaranteeing the efficiency of your industrial operations. Our head pulleys are custom-designed to deliver optimal performance, regardless of operating conditions.

The drive pulley, also known as the drum motor, is connected to the gear motor, which transfers the mechanical energy needed to drive the belt. This pulley is generally the most heavily stressed part of a conveyor, as it bears the highest loads due to the gear motor’s torque and the belt’s tension. Its manufacturing therefore requires considerable expertise to meet strict standards of quality and durability.

Design and lagging for optimal performance

The choice of a conveyor head pulley must take into account several factors: load capacity, belt speed, tension, and conveyor configuration.

To ensure the smooth operation of the conveyor system, the drive drum pulley is generally machined with a crowned profile. This profile helps keep the conveyor belt centered, thereby enhancing overall stability and reducing maintenance needs. In addition, the pulley’s lagging plays a key role in providing optimal traction and minimizing belt wear. Therefore, ALTEMA offers rubber or ceramic lagging to enhance grip and extend the lifespan of the head drum pulley. Finally, the high mechanical stresses on the pulley require precise dimensioning and carefully selected materials to ensure durability, even in the most demanding environments, such as quarries, mines, or heavy industries.

Need for

Technical advice?

Call our drum experts

A range of drum pulleys for all sectors of activity

ALTEMA's experience enables us to meet both classic conveyor pulley and handling drum pulley requirements, as well as more specific needs in all sectors of activity: mining, quarrying, recycling, fertilizers, ports, food processing.

+10,000 Drum pulleys per year

+10 Business sectors

+500 satisfied customers

Do you already have the dimensions of your drum pulley ? Send us your pre-filled request for a quick quotation using ALTEMA drawings.

Our Lagging for Head Pulleys

The primary function of a conveyor head drum pulley is to drive the conveyor belt effectively while maintaining optimal adhesion. In most cases, this motorized pulley is equipped with specialized lagging, such as diamond-patterned rubber or ceramic lagging, both carefully selected for their anti-slip properties. These technical choices play a key role in providing belt traction, especially when the conveyor is handling heavy loads or operating in demanding conditions.

Adhesion as a Key Performance Factor

Adhesion between the head pulley and the belt is crucial for the conveyor’s ability to move materials efficiently. Insufficient grip can cause slippage, reduce drive efficiency, and lead to premature belt wear. That’s why it’s essential to choose lagging tailored to the requirements of each industrial application. For example, in wet or abrasive environments, ceramic lagging provides excellent adhesion and enhanced wear resistance, while diamond-patterned rubber is ideal for standard applications requiring strong grip.

Customized Solutions

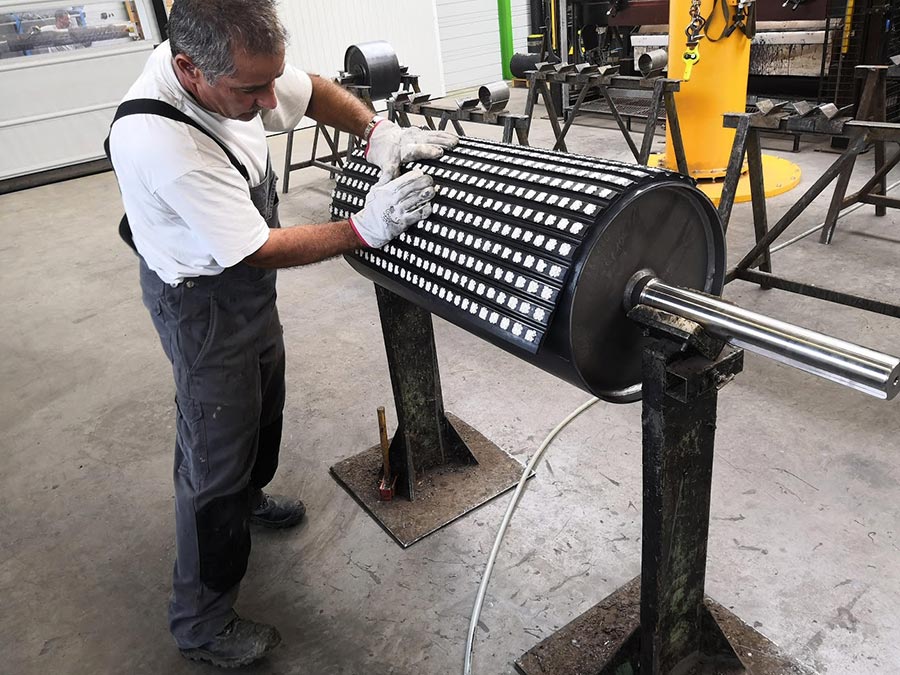

ALTEMA leverages over 25 years of experience in belt conveyor pulley design and offers a comprehensive range of custom lagging options. Our experienced teams are ready to assess the specific needs of your facility and guide you in choosing the most suitable lagging to meet your productivity and durability goals. Whether for a standard conveyor drive pulley or a more complex configuration, we analyze operational conditions, usage frequency, and load demands to select the lagging that delivers the best performance.

Technical support in defining your products

At Altema, we work closely with our clients to analyze their needs and provide customized solutions tailored to their industrial environment. Our team’s expertise ensures the ideal technical and economic balance for seamless integration of the drum pulley into the conveyor system.

If you’re looking for a trusted partner for your drive pulleys, feel free to contact us and discover how we can optimize your conveyor systems with high-quality head pulleys or drum motor.

Altema services

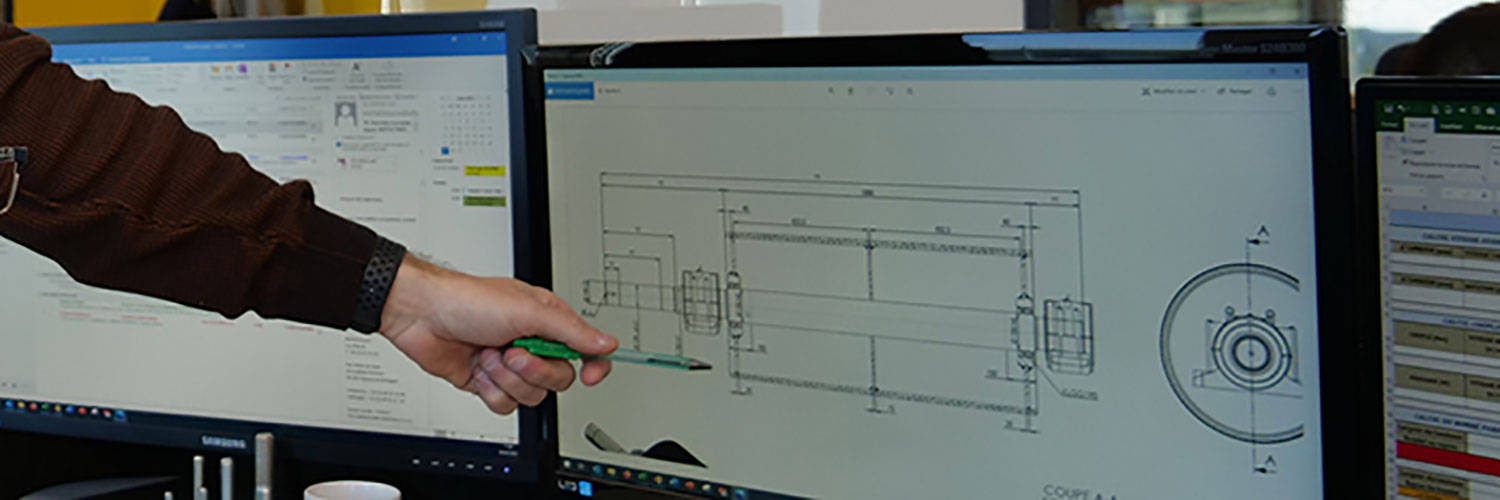

RDM DIMENSIONING

ALTEMA's Engineering Department is able to dimension and verify conveyor drum pulleys and elevator pulleys using its RDM and 3D CAD calculation software.

Static and Dynamic Balancing

ALTEMA offers balancing solutions and services for high-speed conveyor pulleys, to keep them running at peak performance.

TECHNICAL SUPPORT

Depending on the application, the field of activity, the transported material and the climatic conditions, ALTEMA offers you specific solutions to optimise your products and improve your performance.

Other classic conveyor pulleys

tail pulley

The tail pulley, typically located opposite the drive section, ensures precise alignment of the conveyor belt and maintains optimal tension, thereby reducing the risk of premature wear.

Snub pulley

The snub pulley increases the contact surface between the conveyor belt and the adjacent pulley, playing a key role in ensuring optimal traction and maintaining stable tension.

Take up pulley

The take-up pulley regulates the belt tension according to the load being transported. This ensures smooth conveyor operation and prevents failures caused by improper tension.