Technical support

ALTEMA’s teams work with their customers on a daily basis to help them define their conveyor drums:

- Choosing the right lagging type for the application or product being conveyed

- Advice on paint type depending on the environment (e.g. aggressive, corrosive products, marine environment)

- Advice on the choice of materials

- Advice on dynamic or static balancing

- Choice of shaft/flange connection type

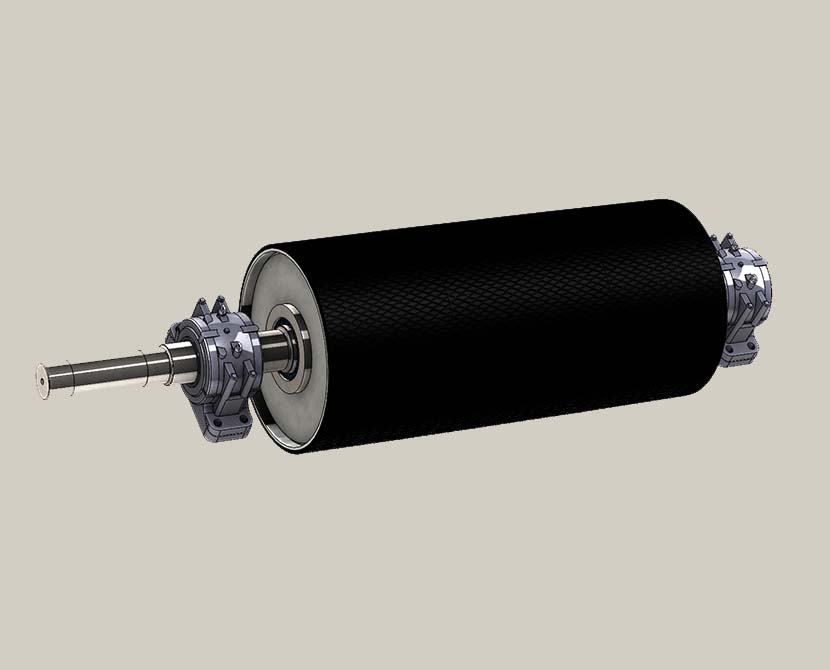

DIMENSIONING your drum pulleys

The engineering department can advise you on sizing and design according to the field of application and the product conveyed. Our services range from the sizing control to the design, if the efforts are communicated to us, right up to the drafting of a calculation note on request. Thanks to our calculation software, we can help you design your conveyor pulleys.

For this purpose, you will be sent a questionnaire containing the data required for sizing. Based on these elements, we will be able to provide you with a calculation note which will show, among other things, the following results:

- Torsional safety coefficient

- Flexural safety coefficient

- Fatigue margins

Drum pulley sizing adjustment

In specific cases, this software also enables us to adjust drum sizing by varying various elements, including the following parameters:

- Shaft material and dimensions

- Different connecting radius

- Flange thickness

- Connection types

Thanks to our calculation tool, we can provide you with advice and assistance in sizing your conveyor belt drum.